Rolled Zinc

Rolled Zinc is produced as sheet, strip, plate, rod and wire, and in many compositions and alloys, depending on the requirements of the end product. Today, zinc sheet is typically produced by continuous casting/rolling. Zinc is melted in an induction furnace, and the molten metal is poured between the two endless bands of a Hazelett machine, where it solidifies. The continuous ‘ingot’ delivered at the other end can be more than 1 meter wide and from 10 to 20 mm thick. The endless strip is fed continuously to a rolling mill, which reduces the thickness to the desired level in successive passes, after which it is cut to size and coiled.

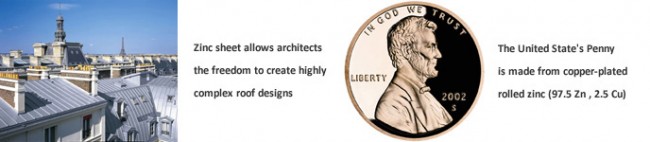

Zinc sheet is used extensively in the building industry for roofing, wall clading, gutters and downspouts, flashing and weathering applications. In this day and age, using materials that pollute during manufacture, use and disposal falls far short of green-building initiatives. During the last 40 years, roofing materials have accounted for 7 to 10 percent of existing landfill space.

Zinc, on the other hand, is far less likely to enter the waste stream. When properly installed, a zinc roof or wall system can last up to 100 years. In fact in Europe, where zinc use is more prevalent, roofs, gutters and railings have been known to last for generations. After their “useful life” these products are then recovered and reused at an impressive rate. In Western Europe, for example, an extraordinary 90 percent of rolled zinc is recovered from roofs and rainwater systems every year, amounting to the equivalent of 110,230 tons (99,999 metric tons).

In addition to architectural applications, rolled zinc is also used in graphic art to make plates and blocks, as well as battery cans and coinage.